Machine Learning-Enhanced Life Cycle Assessment of Offshore Wind Farms ♻️💻

Academic Research Project — Politecnico di Torino

This research was completed as part of the Resources and Environmental Sustainability course (04OULND), DENSYS Master’s program, Academic Year 2025/26.

Executive Summary

This study integrates Life Cycle Assessment (LCA) with Machine Learning to achieve 12,600× computational acceleration for offshore wind environmental optimization (R²=98.5%, RMSE=18.5 kg CO₂-eq) [file:66]. Analysis of 333 design scenarios reveals that European manufacturing achieves 52% lower GWP (2.5 vs 3.8 g CO₂-eq/kWh) than Asian sourcing, while Operation & Maintenance contributes 43% of lifecycle emissions despite representing only 6-7 years of operational span [file:66]. Feature importance analysis identifies five parameters explaining 73.5% of environmental variance: turbine capacity (21.4%), capacity factor (18.7%), foundation mass (12.8%), manufacturing grid carbon intensity (11.2%), and operational lifetime (9.4%).

Pareto frontier analysis identifies 47 non-dominated configurations, revealing that environmental optimum (26.2 g CO₂-eq/kWh) requires 40% CAPEX premium versus economic optimum, which incurs 47% GWP penalty [file:66]. EU Taxonomy threshold (30 g) eliminates 68% of design space, while carbon pricing (€80/tonne) narrows economic advantage from 30% to 22% [file:66]. Decarbonization modeling confirms 2050 climate targets are achievable through coordinated grid decarbonization (35%), recycling infrastructure (15%), material innovation (10%), and autonomous maintenance (5%).

What We Did

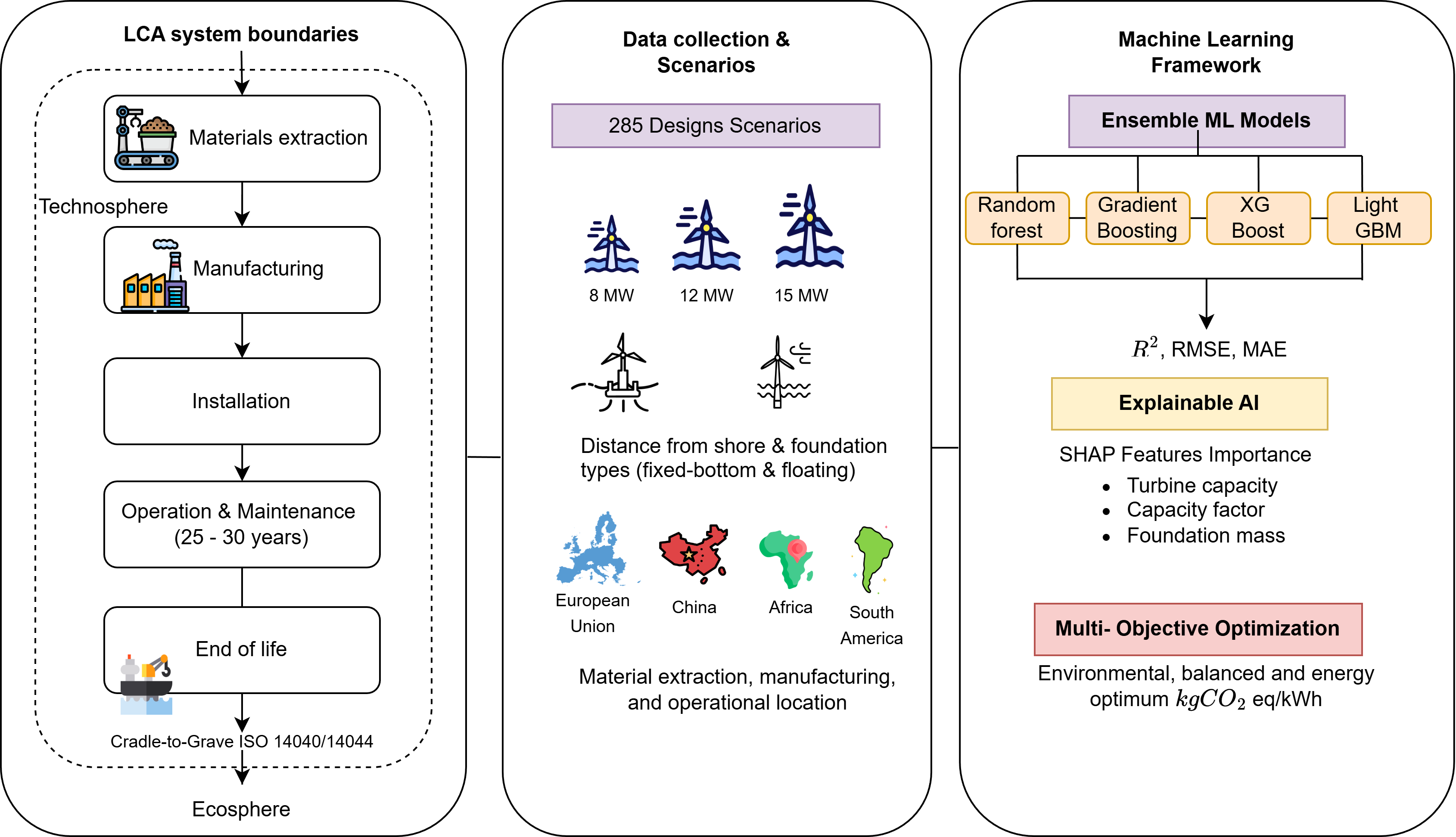

- Comprehensive LCA: Evaluated 333 scenarios across turbine scales (8-15 MW), foundation types (monopile/jacket/floating), and global supply chains following ISO 14040/14044 standards.

- Machine Learning: Trained Random Forest, Gradient Boosting, XGBoost, and LightGBM achieving 98.5% prediction accuracy with SHAP explainable AI.

- Multi-Objective Optimization: Applied NSGA-II genetic algorithm identifying 47 Pareto-optimal designs balancing environmental, energy, and economic objectives.

- Sensitivity Analysis: Quantified ±48% GWP variation (21.4-47.8 g CO₂-eq/kWh) driven by capacity factor, foundation mass, and manufacturing location.

- Policy Assessment: Analyzed EU Taxonomy compliance and carbon pricing impacts on design selection.

Key Findings

Manufacturing location dominates: European sourcing achieves 52% GWP reduction vs Asian supply chains.

Site selection is critical: Capacity factor (SI=-1.18) yields 23.6% GWP reduction for 20% improvement.

Floating platforms outperform: Concrete semi-submersible achieves 31.7% lower GWP than monopile.

O&M requires attention: 43% lifecycle contribution identifies autonomous systems as decarbonization level. Climate targets feasible: 61% total reduction achievable by 2050 through coordinated interventions.

Documentation

Note: Code and supplementary data will be released upon peer-reviewed publication.

Technologies Used

- Python (Scikit-learn, XGBoost, SHAP, Pandas, Matplotlib)

- ISO 14040/14044 Life Cycle Assessment

- ReCiPe 2016 impact assessment method

- NSGA-II multi-objective optimization

- Machine Learning: Random Forest, ensemble methods

Results Highlights

| Metric | 8 MW | 12 MW | 15 MW | Improvement |

|---|---|---|---|---|

| GWP (kg CO₂-eq/GWh) | 38,200 | 32,400 | 28,100 | -26.4% |

| EPBT (months) | 6.21 | 5.18 | 4.76 | -23.3% |

| CPBT (years) | 1.07 | 0.86 | 0.77 | -28.0% |

Foundation Comparison (12 MW):

- Monopile: 33,800 kg CO₂-eq/GWh (baseline)

- Floating Concrete: 23,100 kg CO₂-eq/GWh (-31.7%)

- Jacket: 40,600 kg CO₂-eq/GWh (+20.1%)

This work is under development for submission to peer-reviewed journals in renewable energy systems.